In case you are a true gun lover, you might be well aware of the importance of keeping the cartridges clean.

The most common method employed to keep the cartridges clean is to use brass cases.

The brass case is the best choice to store your cartridges clean.

These are often recommended due to following reasons:

- Resistant to corrosion

- Property to withstand any harsh temperature

- Easy extraction and ejection without a material tear

- Option to reload the case any number of times according to your convenience

Well, cleaning your brass for reloading is equally important to let the media drain out.

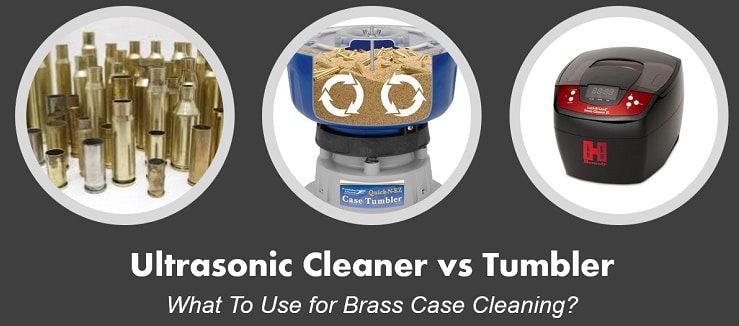

Two most reliable and effortless cleaning techniques that are being used are as follows:

- Tumbling cleaning

- Ultrasonic cleaning

Ultrasonic Cleaners for Brass Cleaning

The most recent and efficient method of cleaning brass shells is ultrasonic cleaning.

This is also termed as a stainless media wet tumbling method and once installed it can even be used for cleaning your gun parts too.

This is the best method of cleaning brass when it comes to users of pistols and high volume loaders.

You will need to take the primer first and separate them before going ahead with cleaning on the whole.

This is also the best method as you can go ahead with cleaning and drying simultaneously.

Just as the name suggests, ultrasonic cleaners such as the Hornady lock n load cleaner makes use of water for the process of cleaning brass.

This ultrasonic gun cleaning equipment contains a built-in basket that can be used to deposit cartridges. The basket is then put into the container which is already filled with water and cleaning solvent.

This cleaning solvent will then do the job of taking away carbon and other waste deposits from brass.

Yet another added advantage of the ultrasonic method of cleaning is that it takes less than fifteen minutes so as to do its job in an automated way.

This means you need not invest more of your valuable time or effort into cleaning your guns and brass cases.

Once the cleaning is complete, you need to take out the cartridges. With wet cleaning, the brass needs to be dried soon after it’s taken out from the container.

The most natural method of drying is to place the element to a towel and then keep it under the sun and this way the drying process is complete.

The most added advantage of wet cleaning is that it cleans shells inside out and allows better cleaning experience than any other traditional method.

With ultrasonic cleaning, you need not worry about items getting jammed inside the lid and also it offers a cost-effective solution to your need.

The only factor that needs your attention is drying which is not a tough task as the most natural energy shall do the job for you.

Using Tumblers for Brass Case Cleaning

The method of cleaning cartridge and shells by employing the tumbler technique is the most traditional method of cleaning gun parts.

This method is also termed as the dry method and most of the time it requires the addition of media which is made of natural materials.

The media can be changed or replaced on a regular process so as to get better results from your cleaning process.

The contains a plastic bowl. The bowl is mounted on a motor that is electric and this helps in the vibrating motion of tumbler along with contents in it.

The case that needs to be cleaned is immersed inside the lid along with stainless media. Once the lid is closed, the motor is allowed to run.

Usually, it takes more than half an hour to remove dirt from the brass. The only negative aspect of tumbler cleaning is the sound that comes out while the motor is running.

The next important concern when it comes to cleaning brass using the stainless tumbling technique is to ensure that the dirt removed from the brass does not mix with cartridge again.

To work on this end, most tumblers have built-in filters that work as a storage space for accumulation of dirt removed from brass while the cleaning process is done.

With tumbling technique (using the best tumbler for brass) you need to be aware of the fact that you do not mix calibers as this might result in jamming of contents inside.

With the tumbling method of brass case cleaning, the final shell product is neat and clean and also allows the firearm to function smoothly and effectively.

Difference between Both and Which One To Choose?

The most important difference between both techniques is the ease with which it operates.

Compared to the tumbling technique ultrasonic process emits lesser sound and also provides a better cleaning solution compared to tumbling technique.

With the ultrasonic process, you will just need to ensure that the drying is done perfectly and that the moisture content does not stick to the shells.

Both techniques carry their own advantages and disadvantages.

Making a choice between these two right methods is your choice and you need to be careful about the right method that can reduce your efforts of cleaning gun parts than accumulating it.